Necessity is the mother of invention....

A somewhat similar parallel to this might be "tight spaces are the mother of... cheap alternatives" ?!

Ok, so we all have this "situation" where equipment we buy starts flooding our workspace until you literally are stubbing you toes against them even getting up from your chair.

Same thing happened me (the flooding part, not the toe stubbing part) so having observed some narrow spaces in my workspace, I decided the best way to organize things would be some (only 2) racks.

Easier said than done.... My workspace is at the second level of the house, up two flights of stairs, one more steep than the other... also the last set of stairs is this weird spiral thing, so you can imagine a normal 19 inch rack is impossible to haul up there.

Huh, should see me hauling VNAs and Optical analyzers up those stairs... my god, that's a laugh for anyone....

But I digress. So, why not have a rack in pieces and assemble it upstairs. Wel, how about I up one on this one... how about I make my own cheap rack system... OK, cheap-ish.

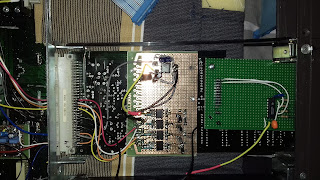

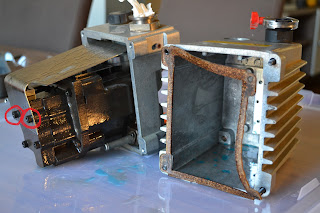

The big rack, in all its glory

The structure is made from 2mm thick, 40mm wide angle iron.... A keen eye will see that the dimensions are slighly bigger that the standard 19 inch racks system.. that's because my equipment does not all have the rack handles, so I wanted an wasy way to get my hands on the sides of the equipment to get it in and out of the rack.

Hence, I came up with these measurements (more out of chance than maths and intent, but hey...) 61.5 cm deep x 56.5 cm wide or 24.2'' x 22.2''

This is enough so that I can man-handle units in and out of the rack, including big lumbering things like an Advantest optical spectrum analyzer that weighs the equivalent of a medium-sized anvil... and is just as nasty to handle.

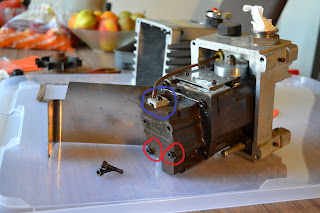

Also, the racks are on wheels so they can be moved around. The big one, though, is meant more to just sit there and look pretty than be moved around. The shorter rack was designed with mobility in mind. Meaning, it's supposed to take equipment that is needed for whatever measurements I'm doing and sit next to my desk. After I'm done, it goes back to it's corner and out of the way.

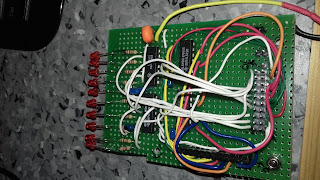

The shorter rack I made

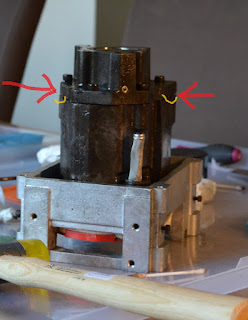

The DUT shelf on the mid-height rack, sitting next to my desk. Really handy for measuring stuff and having a nice clean desk

The stand for the DUT with its rackable mount

And it works pretty well in practice. I also added a nice "porch" for the DUT to sit on when doing measurements or for a scope or whatever else is needed. The "porch" can be moved up or down easily as it has this really nice and fast mating system.

Tell us the price, son...

So, the tall rack cost about 270 Euros, that's including wheels, all the angle iron, screws (which there's a boat load of), plywood and cross-braces. Ok, I know that there might have been a chance to actually get a cheap 19 inch rack at auction that's somewhere around this price, but because of the logistics of getting one delivered to my home, I just couldn't be bothered. Plus, I made a rack all by myslef... how cool is that.

Ok, it doesn't look like something you'd write home about, I know.... but considering that the tall one is now holding in excess of 250 kilos of equipment and is stable and still moveable is something to note.

Price aside, this was also the first rack I made, so once I started building, it took me something like 3 afternoons (as in about 3 or 4 hours every day) and 2 whole days (meaning a Saturday and Sunday) to have everything together and stable. Once I had my head around the whole thing and knew how everything should go together, the second rack took only a whole weekend to cut, screw and assemble.

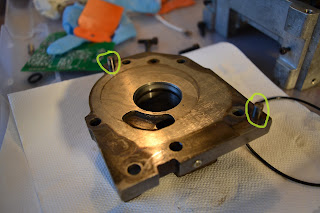

cross braces made from steel T profiles

Why not those modular aluminium extruded profiles, I hear you ask ?

Well, turns out that a) they're kinda expensive and b) it's a real hassle to figure out all the bits and bobs you need to put everything together. For the tall rack, my calculations stopped at around 250 Euros for the 4 vertical legs, wheels and 4 rafters. Adding to that another 150 Euros in things to keep everything together and I started to look for altenatives. The end result may not be as sexy, but it does the job and I get extra "cool" points.

Hope you enjoyed this and maybe it inspires you to get cracking on your own thing. And if you do, please make it pretier than mine... and share some pics.